Jaguar Land Rover turns to drones to conduct plant inspections

Jaguar Land Rover (JLR) is trialling drone technology at its Electric Propulsion Manufacturing Centre (EPMC) in Wolverhampton, in the UK.

The British marque says the technology has the potential to reduce machinery and site inspection time by up to 95%, as drone inspections can cut a four-hour process down to about ten minutes.

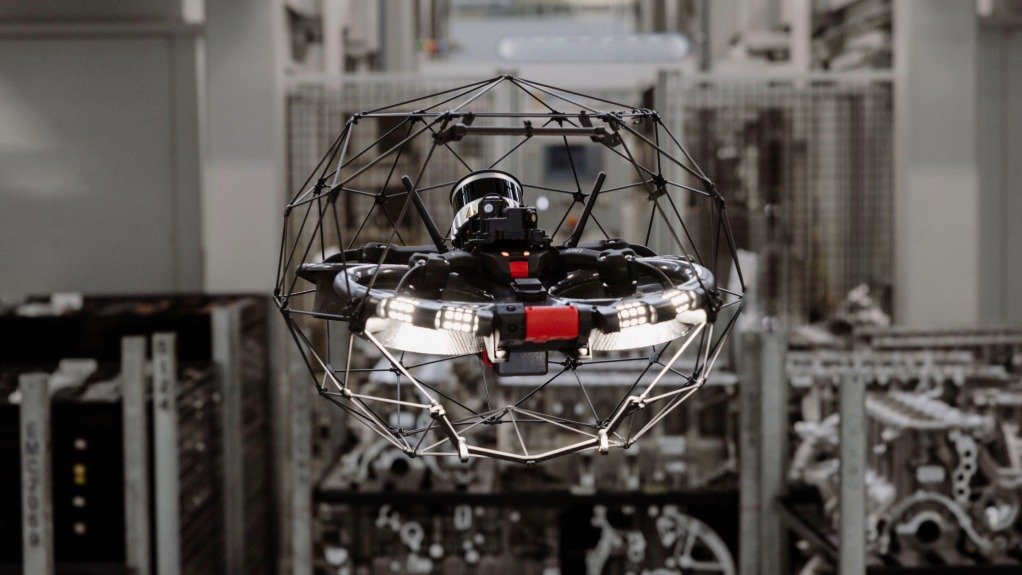

The Elios 3 drone by Flyability can reach high and confined spaces, allowing maintenance teams to inspect equipment from the factory floor, which reduces risk and eliminates the need for elevated platforms.

Operated via tablet, the drone delivers a live three-dimensional (3D) map to identify and troubleshoot any problems.

“As we transform our facilities, we are rethinking every part of our factories, including how we maintain and operate them,” explains industrial operations executive director Nigel Blenkinsop.

“Trials like this one with advanced drone technology are helping us improve employee safety, reduce maintenance downtime and operate more efficiently.

“Just as importantly, they are helping upskill our people in the latest digital technologies, ensuring our teams are part of our factories of the future.”

The drone on trial uses light detection and ranging (LiDAR) sensors to send out laser light pulses, which bounce back to the drone when it hits an object.

By timing how long the pulses take to return, the drone calculates distances, and in doing so, it creates detailed 3D maps of the surrounding environment.

The drone also features a thermal camera to help pinpoint overheating components or insulation failures, which helps to optimise energy use.

Following successful trials at EPMC, the next test round will take place at JLR’s Logistics Operations Centre in Solihull – a vast warehouse space equivalent to 13 football pitches, or roughly 91 800 m² in size.

Here, the drone will be equipped with barcode scanners to automate inventory checks, which will replace the normally manual process.

JLR believes this will help improve safety, reduce errors and support smarter decisions on space, stock levels and supply flow.

The drone initiative is part of a £18-billion investment by JLR over the five‑year period from the 2024 financial year onwards. It also supports the car manufacturer’s Future Skills programme, which aims to train 29 000 employees in electrification and digital skills.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation